Our projects

CHECK OUT OUR PROJECTS

BMW

BMW

The BMW name is an abbreviation of Bayerische Motoren Werke – the factories near Munich, Bavaria, created in 1913. In the first three years after its establishment, aircraft engines were created, and later car engines.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2012 | BMW 1 Series – F20/F21 | Electrical Installations – Side Frame | Leipzig, Germany |

| 2012 | Mini Cooper – F55/F56/F57 | Electrical Installations – Side Frame Rear Compartament | Oxford, England |

| 2013 | Mini Cooper – F56/F57 | Electrical Installations – Side Frame | Born, Netherlands |

| 2013 | BMW 7 Series – G11/G12 | Electrical Installations – Doors Line | Dingolfing, Germany |

| 2014 | BMW X1 – F46/F48 | Electrical Installations – Side Frame Rear Compartament | Regensburg, Germany |

| 2014 | BMW 5 Series – F10 | Electrical Installations – Doors Line | Shenyang, China |

| 2015 | BMW 5 Series – G30/G31/G32 | Electrical Installations – Doors Line | Dingolfing, Germany |

| 2015 | BMW X3 – F25 | Electrical Installations – Doors Line | Dadong, China |

| 2016 | BMW X1/X3 – G01/G02 | Electrical & Mechanical Installations Framing Line, Metal Finish | Spartanburg, USA |

| 2017 | BMW X5/X6/X7 – G05/G06/G07 | Electrical & Mechanical Installations Framing Line, Rear Compartament Side Frame | Spartanburg, USA |

| 2018 | BMW X5 – G05/15 | Electrical Installations – Metal Finish Under Body | Spartanburg, USA |

| 2019 | BMW X5 – G05/15 | Electrical Installations – Metal Finish Under Body | Spartanburg, USA |

| 2021 | BMW 6 Series – G60/G90 | Electrical Installations – Seitenwand | Dingolfing, Germany |

Mercedes

Mercedes

Represents the oldest car manufacturer. At the end of the 19th century, Gottlieb Daimler and Carl Benz created the first car powered by an internal combustion engine. Mercedes comes from the name of the daughter of Emil Jellinek, one of the first Daimler and Benz dealers. Jelinek was consul of the Austro-Hungarian Empire in Nice and obtained the right to sell cars created by Daimler and Benz under the name Mercedes.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2013 | Mercedes-Benz C Classe – W205 | Electrical Installations – Side Frame | Bremen, Germany |

| 2014 | Mercedes-Benz A Classe – W176 | Electrical Installations – Side Frame | East London, South Africa |

| 2020 | Mercedes-Benz C Classe – W209 | Electrical Installations – Framing Line | Bremen, Germany |

| 2022 | Mercedes-Benz S Classe – W500 | Measurement Profinet | Sindelfingen, Germany |

| 2025 | Mercedes-Benz Vito | Electrical & Pneumatic Installations – Fixtures, Grippers | Oradea, Romania |

Audi

Audi

In 1901, a car company was founded by August Horch under the name “Horch”. After 9 years, the founder was forced to leave the company and created a new company. Colleagues sued him for using the same name for the cars produced in the new company and he had to change it after losing the lawsuit. His name “horch” meant “to hear / listen”, and his saving idea was to translate it into Latin “Audi!”. The name is also an acronym for Auto Union Deutschland Ingolstadt. Auto Union is a joint venture of 4 manufacturers from interwar Germany from which comes the logo with the 4 circles.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2014 | Audi A4 – B8 | Electrical Installations – Side Frame | Ingolstadt, Germany |

| 2016 | Audi A8 – B8 | Electrical Installations – Framing Line | Neckarsulm, Germany |

| 2021 | Audi A4/A5 – AU40/A58/A59 | Electrical Installations – BHVS Grippers & Fixtures, Integration BHVS BHVT, LTHL, LTHR, BHUG, BHHT, BHTS | Neckarsulm, Germany |

| 2021 | Audi A4 – AU40X | Electrical Installations – URW1 Relocation & Integration | Neckarsulm, Germany |

| 2021 | Audi A5 – AU58X | Electrical Installations – RHAL, RHAR | Neckarsulm, Germany |

| 2021 | Audi A4 – AU40X | Electrical Installations – Relocation to Audi Neckarsulm | Grundau, Germany |

| 2022 | Audi A4/A5 – AU40X/AU59X | Electrical Installations – Frontklappe/Heckklappe | Neckarsulm, Germany |

| 2022 | Audi A5 – AU592 | Electrical Installations – Boden Hinten Lines | Neckarsulm, Germany |

| 2023 | Audi A4/A5 – AU581/AU40X/AU59X | Electrical Installations – Boden Hinten/klappen | Neckarsulm, Germany |

| 2024 | Audi A4/A5/Q6 etron | Electrical Installations – Finish Line | Ingolstadt, Germany |

Wolkswagen

Volkswagen

Volkswagen means “people’s car” in German. In 1934, Hitler decreed that any German should afford a car. The car had to be able to carry two adults and three children at a speed of 100 km / h and cost no more than a motorcycle. The program was named after a Nazi recreation organization that means “Force through Joy.” Ferdinand Porsche was in charge of designing the car, which was produced by Daimler. Later, the car was named Beetle and sold over 21 million copies, remaining in history as the most famous car.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2013 | VW Passat – B8 | Electrical Installations – Framing Line | Emden, Germany |

| 2021 | VW ID.4 | Electrical Installations – Under Body | Emden, Germany |

| 2022 | VW ID.4 | Electrical Installations – Frontklappe/Heckklappe | Emden, Germany |

| 2023 | VW ID.3 – 310 | Electrical Installations – Under Body | Wolfsburg, Germany |

| 2024 | VW ID.3 – 310 | Electrical Installations – Framing Line/Under Body/Integration | Wolfsburg, Germany |

| 2025 | VW ID.3 – 310 | Electrical Installations – Framing Line/Under Body/Measurement protocol | Wolfsburg, Germany |

Porsche

Porsche

Ferdinand Porsche built the first Volkswagen car in 1936, and two years later created the first Porsche car. The first Porsche models were created with components from Volkswagen, and since 1963, the company has produced cars with its own components entirely

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2015 | Porsche Panamera – PO 622/623/623-1 | Electrical Installations – Framing Line | Leipzig, Germany |

Volvo

Volvo

The company was created in 1927 by some engineers who retired from a bearing factory. The name “Volvo” means “I roll” in Latin. The brand is certainly associated due to the seat belt which has a three-point fastening system and other innovations that ensure the protection of passengers.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2013 | Volvo XC90 – V526 | Electrical Installations – Side Frame | Olofstrom, Sweden |

Opel

Opel

The name comes from the German Adam Opel who founded the company in 1899. Later, the company was taken over by General Motors which sold the models under several names. In Great Britain, Opel is called Vauxhall, in Australia, Holden, in Latin America, Chevrolet, and in the United States the cars were sold for a while under the name Cadillac Catera.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2012 | Opel Corsa – D | Electrical Installations – Rear Compartament | Eisenach, Germany |

| 2019 | Opel Grandland – X | Electrical Installations – Framing Line Under Body | Eisenach, Germany |

Saab

Saab

Saab AB (initially About this sound Svenska Aeroplan AB, later SAAB and Saab Group) is a Swedish aerospace and defense company, founded in 1937. From 1947 to 1990 it was the parent company of the car manufacturer Saab Automobile. Between 1968 and 1995, the company was in a merger with the commercial vehicle manufacturer Scania-Vabis, known as Saab-Scania. The two were split in 1995 by the new owners, Investor AB. Despite the split, both Saab and Scania share the right to use the griffin logo, which comes from the coat of arms of the Swedish region Scania.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2011 | Saab 9/5 – YS3G | Electrical Installations – Framing Line | Trollhattan, Sweden |

Jaguar

Jaguar

The company was founded by William Lyons in 1922 and was originally called the Swallow Sidecar. After World War II, the company was forced to change its name due to the negative connotation that the initials SS had. These were associated with the Nazi paramilitary force and were of no interest to Westerners, so the logo was replaced with the current logo.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2020 | Land-Rover – EVOQUE | Electrical Installations – Side Frame | Birmingham, England |

Ford

Ford

The brand name comes from its founder, Henry Ford. The company was founded in 1903 near Detroit, aiming and succeeding in producing production cars accessible to all people.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2012 | Ford Focus | Electrical Installations – Framing Line | Genk, Belgium |

| 2015 | Ford Puma | Electrical Installations – Framing Line | Craiova, Romania |

| 2022 | Ford Explorer – CX740 | Electrical/Mechanic Installations – Framing Line | Koln, Germany |

| 2023 | Ford Explorer – CX740 | Electrical/Mechanic Installations – Framing Line/Underbody | Koln, Germany |

| 2024 | Ford Explorer – CX740 | Electrical/Mechanic Installations – Framing Line/Paint Shop/Body Shop | Koln, Germany |

| 2024 | Ford Puma | Electrical Installations/Modification RGV & Back up | Craiova, Romania |

| 2025 | Ford Puma | Electrical/Mechanic Installations/Modification RGV | Craiova, Romania |

| 2025 | Ford Kuga | Electrical Installations – EMS | Valencia, Spain |

Vinfast

Vinfast

VinFast is a LLC private automotive startup manufacturer headquartered in Vietnam which opened in 2017, a member of the conglomerate organization Vingroup. It is the first Vietnamese car brand attempting to hit global markets

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2019 | Vinfast Lux A/Lux SA/ A-Car | Electrical Installations – Framing Line Side Frame, A-Car | Haiphong, Vietnam |

Magna

Magna

Over 100 years of experience in vehicle production and a broad range of services make Magna Steyr the worldwide leading brand-independent engineering and manufacturing partner for OEMs.

Our extensive range of services covers product groups Engineering Services – from systems and modules to complete vehicle engineering – and Complete Vehicle Manufacturing, where we offer World Class flexible solutions from niche to volume production. So far, Magna Steyr has produced more than 3.7 million vehicles – of 30 different models.

Magna Steyr is the ideal automotive contract manufacturer worldwide to produce vehicles with conventional, hybrid and electric powertrains – in some cases, on the same production line. This further demonstrates the automotive supplier’s experience in electrification and electromobility.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2022 | Magna/Fisker FM29 | Electrical Installations – Under Body | Graz, Austria |

| 2023 | Magna/Fisker FM29 | Electrical Installations – Finish Line | Graz, Austria |

Electrolux

Electrolux

Electrolux AB is a Swedish home appliance manufacturer. The company is the world’s second largest manufacturer of home appliances, after Whirlpool. Electrolux is a manufacturer of vacuum cleaners, washing machines, freezers and refrigerators, and its brands include AEG, Zanussi, Eureka and Frigidaire.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2017 | EOA9S31CX | Electrical Installations – Stoves and Ovens | Tennessee, USA |

Horticola Esma

Horticola Esma

HORTÍCOLA ESMA has a consolidated leading position in the sector. It manages the entire carrot process from beginning to end with 40 employees. In 1965, the Escribano Mato family, grandparents of the current owners, started their operation, growing, washing and marketing carrots. Back then, washing the produce was done with a bag in the river, explains Sergio Escribano, the companys joint manager with his brother Javier. Those were the companys early days, but a promising future was awaiting. In the following years, the excellent work of Benjamín Escribano sets a solid foundation and, in 1995, HORTÍCOLA ESMA is founded and begins its expansion. Four years later, in 1999, the company inaugurates its processing plant in Villanueva de Duero, in Valladolid, and adds potatoes and onions to its product offering. It is worth highlighting that all its products are certified to Global G.A.P Integrated Farm Assurance standards and bear the Tierra de Sabor label that ensures the Quality of agrifood products produced or processed in the Castilla and León region.

| Year | Model & Code | Tasks & Area | City |

|---|---|---|---|

| 2025 | 250117 | Electrical Installations | Valladolid, Spain |

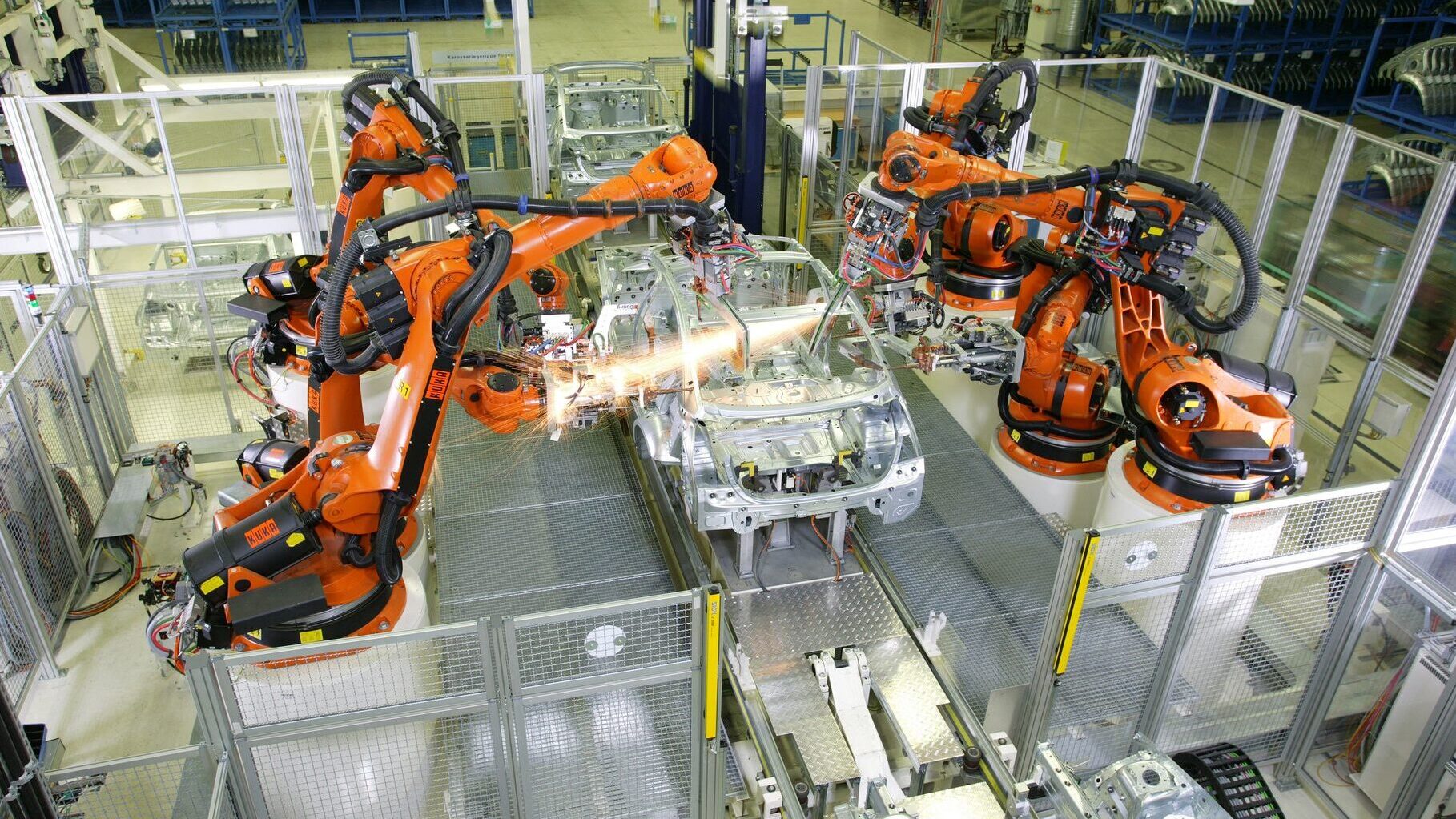

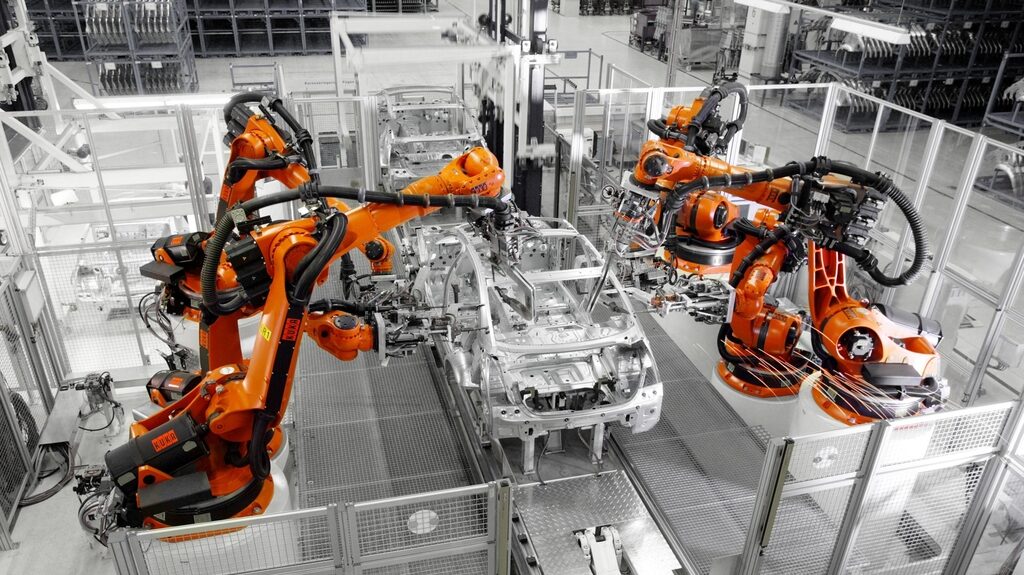

Robotic Welding & Automotive Manufacturing

Many manufacturers have implemented automation into their day-to-day operations, and the automotive industry is no different. In fact, robots have been aiding in the production of cars since 1967 when General Motors (GM) implemented the first industrial robot, called the UNIMATE, which performed spot welding. It wasn’t until the 1980’s that robotic welding began to take off and other automotive companies followed GM’s lead..

Safety

Today, about half of manufacturing robots are used for welding applications, with many being utilized in the automotive industry. It’s easy to see why. These welders increase safety in the workshops by removing the human element from hazardous welding work, keeping workers away from fumes, chemicals, extreme heat and noise, as well as weld flash. These robots also aid in crash safety tests, keeping not only the workers out of harm’s way, but also future consumers..

Cost

Not only have robotic welders increased safety in factories, but they have also saved many automotive manufacturers millions of dollars by doubling, or even tripling, their production time by significantly cutting labor costs. Robots, unlike humans, do not require breaks and can work 24 hours a day, 7 days a week if the manufacturers so choose. Not only, but these robots do not require pay or benefits, thus saving these companies even more..

Efficiency

Not only that, but another reason why automobile manufacturers use robotic welders is their ability to consistently meet industry expectations without delays and within time constraints. They produce accurate, high-quality welds with fewer mistakes and, thus, accidents. Robots can also perform a myriad of jobs, such as welding, painting, finishing, and many others. Their programming allows them to perform intricate tasks with ease. With new industry standards calling for lighter cars, these machines are able to produce tighter welds that can only be accomplished by robots. Robotic welders play a key role in the automotive industry by being able to produce new and advanced, high quality vehicles. As specifications set by the industry become more precise, these robots are able to meet them faster and more efficiently.

Applications

There are two basic categories of robotic welders: fully automatic, and semiautomatic. Semiautomatic welding, often good for limited quantities of products, requires an operator to manually load the parts into the fixture. A weld controller then ensures the welding, torch, and parts all stay with preset parameters. Once completed, the operator removed the finished assembly. In fully automatic welding – ideal for critical welds, repetitive work on identical parts, or if the parts are already hold significant value – there are custom machines, or sometimes even a series of custom machines, set up to load parts, move the torch, weld, monitor the quality of said weld, and then unload the completed part. Some custom machines even have product quality checks added into its programming. Depending on the operation, an operator may need to be present.

.

The Human Element

This is not to say that the human element is obsolete in the automotive industries. Whereas a manual welder can transition from one part to another with relative ease, a machine is often limited to its one specific programmed task. Manufacturers must have techs on staff to maintain, calibrate, fix, and sometimes program these costly investments to keep them running smoothly. It also could take several months for each machine to arrive, depending on its complexity, leaving manual welders to pick up the slack. With regularly high demand from consumers, and productivity and quality being paramount to manufacturers, it is obvious why many car companies automate their assembly lines. The speed and efficiency of machines has drastically changed the way we build cars today, and with constant technological advances improving the process further, it is easy to see the advantages of robotic welding.

.